As the average consumer becomes more educated, rosin and hash products grow in popularity.

2022 was an exciting year for solventless. Hash cups saw more entries than ever before. Producers are getting closer to perfecting their cultivars and processes. The competition is becoming fierce, and consumers are demanding more access to quality solventless products.

Following the release of the WT-CRAFT+, our team of engineers set out to come up with a solventless solution for artisanal, small-batch, and single-source operators. The goal was to design a system with the same state-of-the art technology featured in the WT-CRAFT+. This time, with a simple and modular approach.

The WT-MICRO is the smallest system offered in the WT solventless extraction line, but it does not compromise on quality or functionality. It maintains the sanitary design and efficient workflow that Whistler Technologies is renowned for.

Since the cannabis industry is rapidly evolving, we wanted to design a system that could adapt with the industry.

The WT-MICRO is a modular system, which grows with you. It can be customized to specific needs. Producers can start small, and upgrade as business needs grow.

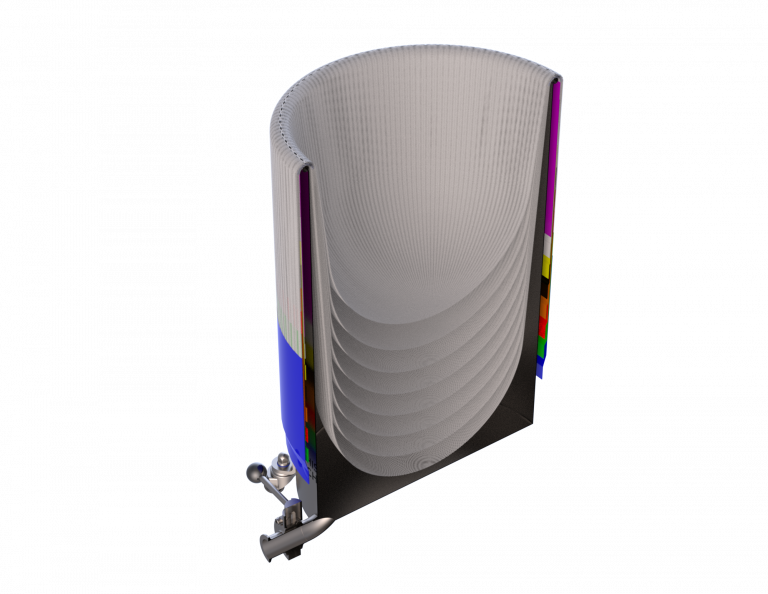

WT-MICRO Agitator Only

The WT-MICRO begins with an agitator-only configuration.

Beginning with just an agitator allows producers to enter the solventless space, at a reduced cost. Meanwhile, the modular nature of the WT-MICRO ensures that producers can efficiently scale up to a complete system when the time comes.

Processors can use existing collection buckets, bags, and a drain pump with the agitator. With this setup, a traditional run and dump process can be operated.

The operator can agitate for a set amount of time, then empty the process water into collection unit(s) lined with bubble bags for collection.

The agitator can be optioned with an integrated sanitary pump, for the convenient transfer of hash water between the agitation tank and collection units. The impeller pumps used on Whistler Technologies systems do not damage trichomes, as there is no compression. The pumps are simply used to facilitate continuous flow. For this reason, there is no fear of lost yields or quality.

The system sits on the ground at a total height of 47 inches. The low overall system height makes cleaning and material changeovers a breeze.

The recommended maximum material input with this arrangement is 15kg WPFF per batch. Processing four batches within an 8-hour shift is possible with two operators, at 60 minutes of agitation per batch. With the agitation-only configuration, ice is loaded into the agitation tank with the material.

If additional throughput is needed, the optional glycol jacket can be added to remove the need for ice entirely. This brings the recommended maximum material input up to 20kg WPFF per batch.

WT-MICRo Run And Dump

We highly recommend pairing a WT-MICRO agitator with two of our newest, redesigned collection units.

The collection units are linked at the bottom to create a reservoir large enough to hold the entirety of the process water. One of them is lined with bubble bags, which are held in place by snap locks. The Whistler Technologies new collection unit with snap locks makes separating, rinsing, and collecting hash easier than ever.

Holding bubble bags while rinsing trichomes is tedious and unnecessary, so we engineered a solution to make life easier for the hashmaker.

The snap locks hold the bag in place, with a fixed 1.5in vertical spacing. Now, the hashmaker can focus on quality control and achieving the right consistency of wet hash in the freeze dryer tray.

The collection bags can be locked at specific heights for the initial filtration of trichomes. Then, they can be repositioned for rinsing and collecting.

WT-MICRO Full System

Ready to cut your labour bill in half, while also reducing cycle times?

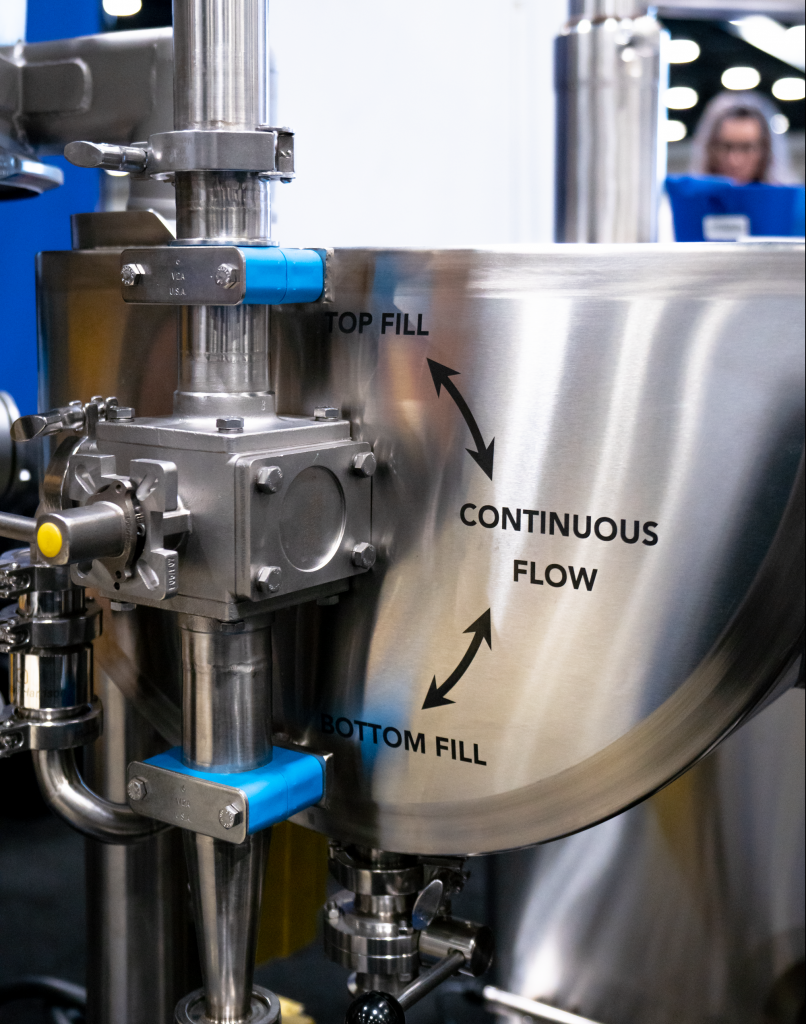

Adding the continuous flow skid brings out the full processing capabilities of the WT-MICRO. Continuous flow facilitates iceless operation, without the need for a glycol jacket or glycol chiller. With the continuous flow skid, a small amount of ice is added to the return container, which frees up space for more cannabis in the agitation tank.

Similar to how the WT-CRAFT+ operates, ice can be added to the return container for active cooling during continuous flow. Process water will overflow back to the agitation tank.

With the release of the WT-CRAFT+, Whistler Technologies introduced the first hash-specific vibratory separator, the WT-VS24, to the market. This custom-engineered separator is what makes our patent-pending continuous flow process possible.

The WT-VS24 hash-specific separator is compatible with the WT-MICRO, and all previous iterations of Whistler Technologies systems.

We have been busy setting up old and new customers with this quiet, but efficient technology. The WT-VS24 separator mounts onto the WT-MICRO continuous flow skid, along with one of the collection units for overflow back into the agitation tank.

This skid can easily wash 4 x 20kg WPFF batches in an 8-hour shift, at 90 minutes of agitation per batch, for yield maximization. Only one operator is required.

Extraction efficiency is no longer dependent on the work ethic of your operator. The WT-VS24 separator removes the majority of the manual labour. Not only is it more efficient to use the hash-specific separator, but the quality of the hash also remains consistent.

With the complete WT-MICRO, simply load the machine, begin continuous flow, and watch as trichomes are perfectly dewatered before being discharged into the collection unit. Hash can be collected at any time.

During collection, the agitator is continuously extracting. For this reason, the system has very little downtime throughout a production day. More mixing time results in higher yields. Let the machine do the work, while you do the paperwork!

Advanced Functionality in the WT-MICRO

Take your WT-MICRO to the next level, with a multitude of upgrade options designed to maximize workflow.

Temperature sensor upgrade

For the hashmaker who wishes to achieve the perfect wash every time, a temperature sensor can be added.

A pharmaceutical-grade temperature sensor can be flush mounted to the agitation tank wall. Easy to clean & 100% sanitary, this sensor provides critical feedback.

Touchscreen upgrade

A washdown rated electrical cabinet with an integrated touchscreen is available as an upgrade, or as a plug-and-play upgrade down the line.

The touchscreen enables recipe functionality for PLC-controlled agitator speeds/ramping, and collection points. The touchscreen also acts as a centralized location for manual control of pump speed, agitator speed, and temperature (if a glycol jacket upgrade is also selected).

Glycol Chilling and Control System

For ultimate control of the extraction process, glycol jacketing and an optional glycol control system is available.

Ice can be completely removed from the extraction process, with the use of a glycol jacket and control system.

Integrating glycol technology with the WT-MICRO ensures that process water is maintained at a stable and consistent temperature. When relying on ice to keep process water cool, the temperature can vary by a few degrees. If process temperatures begin to exceed 1°C, the process water will extract plant compounds such as chlorophyll. This decreases the quality of your hash. Temperatures held close to freezing will keep trichomes brittle, which allows them to be removed more easily.

Continuous flow, combined with active cooling in the agitator, allows the operator to keep their process consistent and controlled. This is for the small-batch operator looking to take their lab to the next level.

The WT-MICRO is truly the first solventless system of its kind, and we couldn’t be more excited.

This cold water extraction system gives smaller producers a chance to enter the industry with high-quality equipment. In addition, established solvent brands now have an efficient and cost-effective way to launch a solventless line.

To learn more about the WT-MICRO or begin your build, visit our dedicated WT-MICRO page.