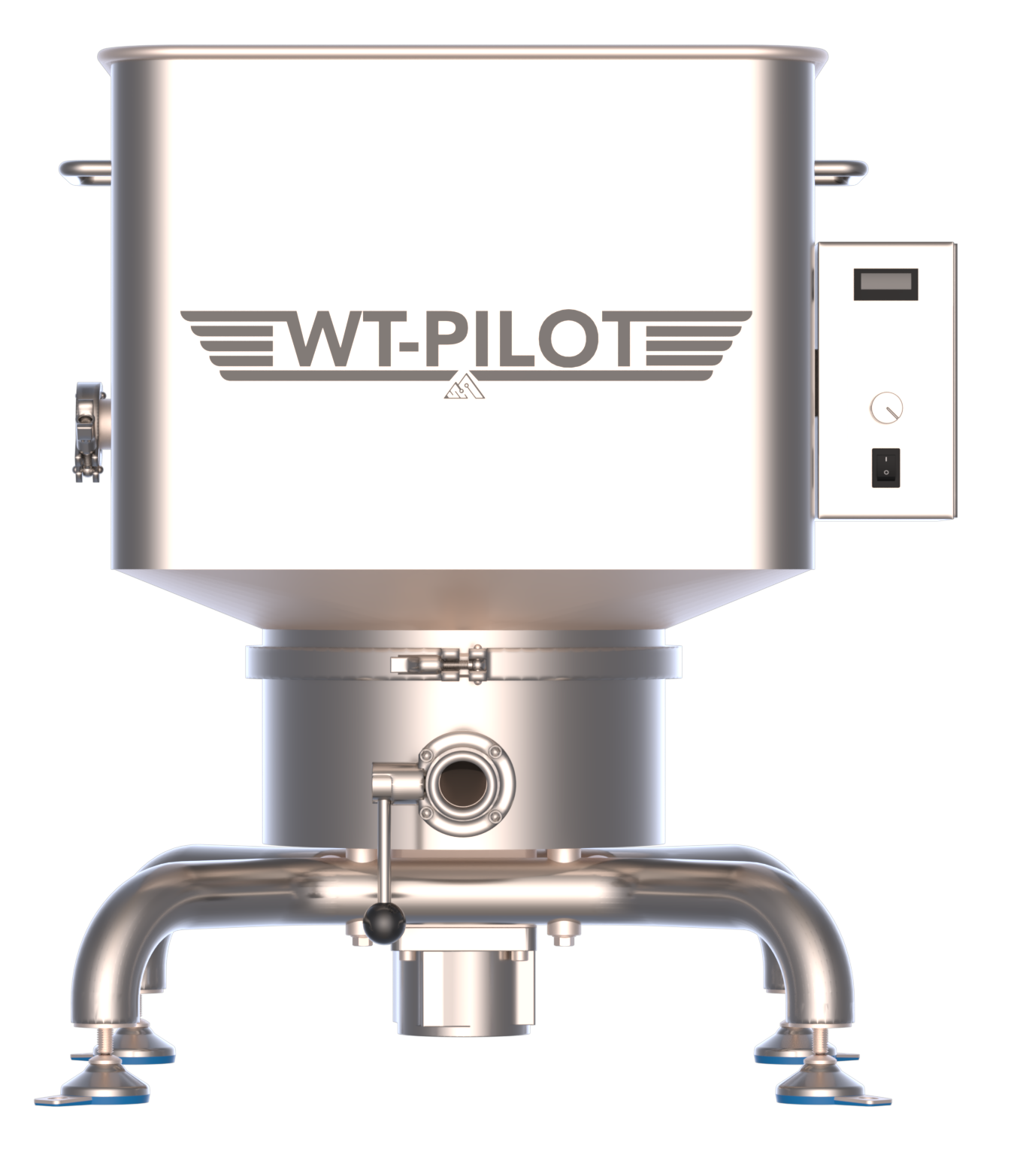

The WT-PILOT redefines small-scale extraction systems with innovation, precision, and an unrivaled sanitary design. It is the only GMP-compliant system of this size on the market.

This solventless system has a 75L agitation tank, complete with our proprietary torus agitation pattern and a 279-micron false bottom filter. It can process up to 10kg of fresh frozen, or up to 3kg of dry biomass per batch run. In a 10-hour shift, a single operator can process 4 batch runs, or up to 40kg of fresh frozen biomass.

Daily Hash Output: Up to 2,800g

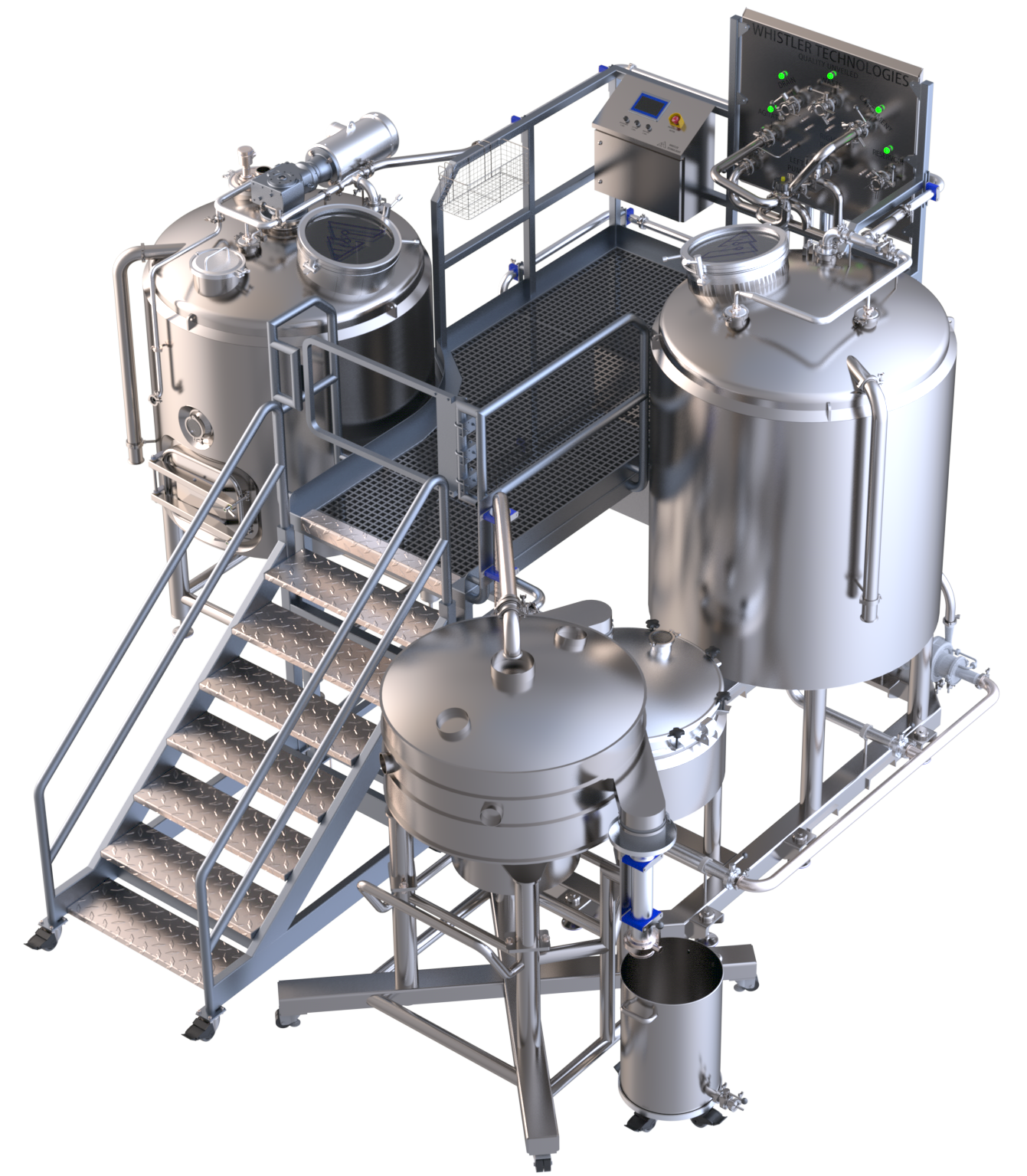

This high-performance system has a 150L agitation tank, complete with our patent-pending double-torus agitation pattern and false bottom filter. It can process up to 20kg of fresh frozen, or up to 6kg of dry biomass per batch run. In a 10-hour shift, a single operator can process 4 batch runs, or up to 80kg of fresh frozen biomass.

Daily Hash Output: Up to 5,600g

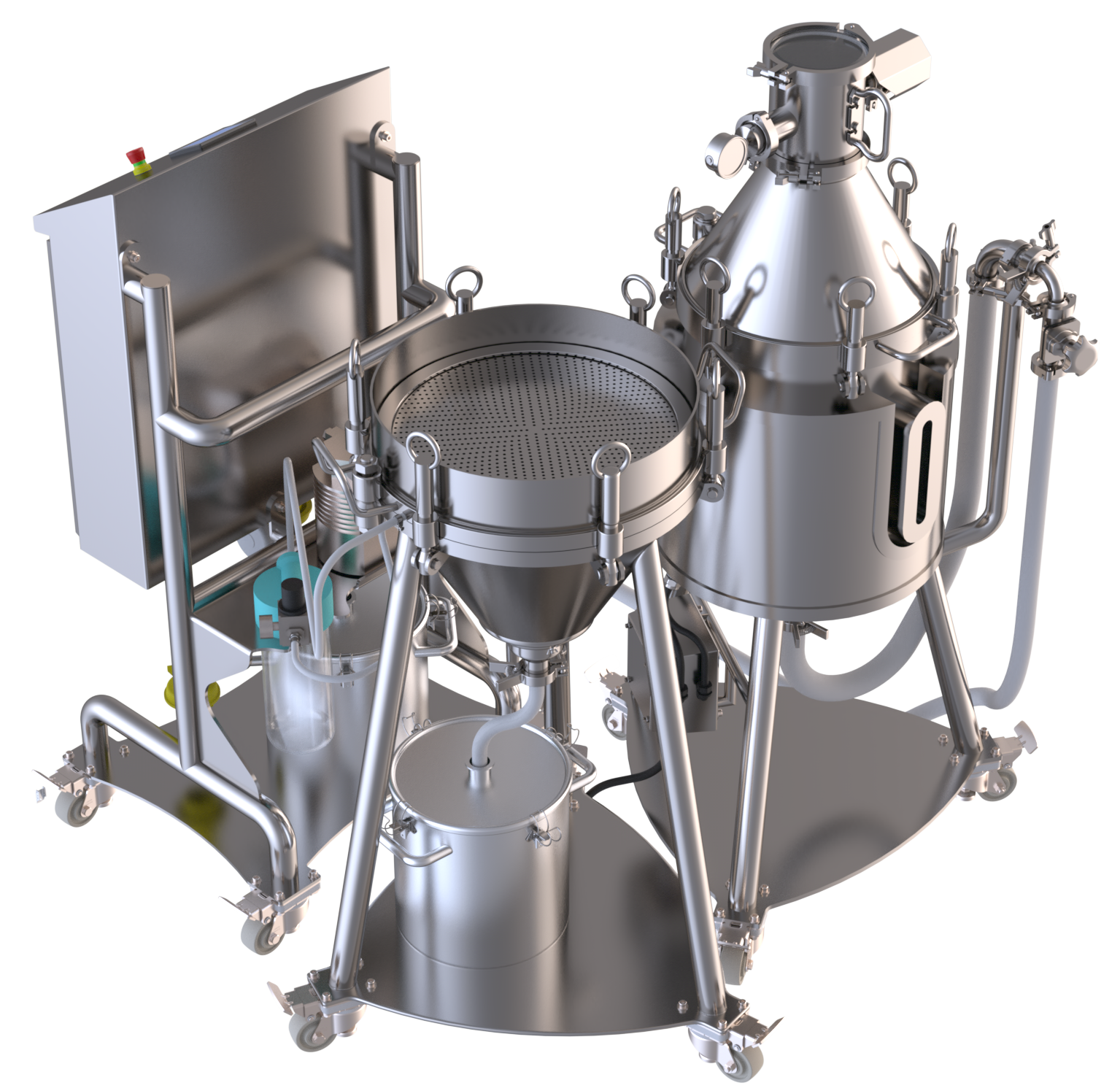

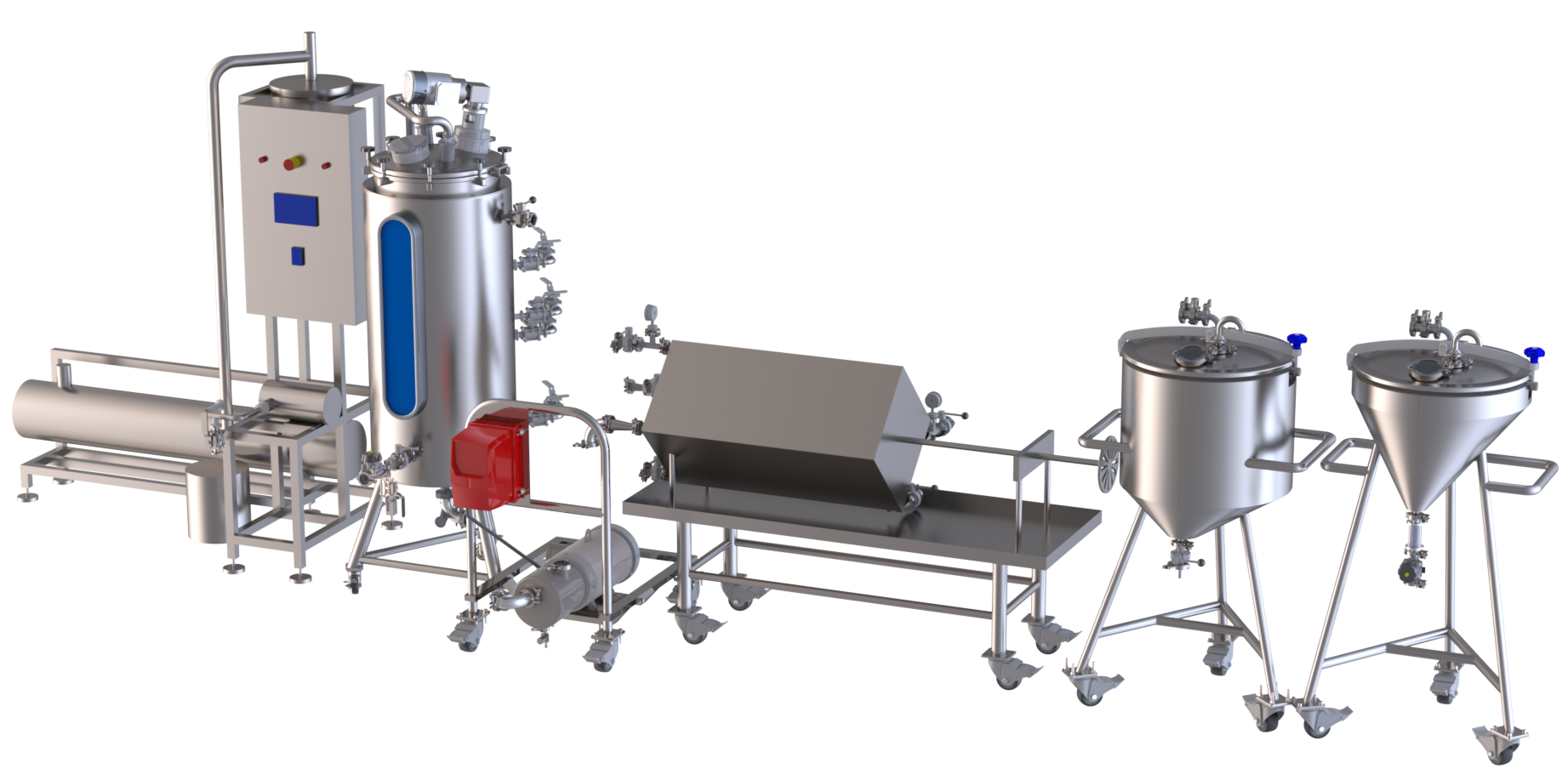

The WT-CRAFT+ is our most innovative design yet. It features a hash-specific separator and is optimized for iceless extraction.

This system has a 300L agitation tank. It can process up to 40kg of fresh frozen, or up to 12kg of dry biomass per run. In a 10-hour shift, a single operator can easily process 4 batch runs, or up to 160kg of fresh frozen biomass.

Processors can maximize the production efficiency of a small area, while maintaining their craft quality. This unit was designed to take hashmaking to the next level.

Daily Hash Output: Up to 11,200g

The WT-2000 is our “farm” scale system, designed for large cannabis, hemp, or hops processors looking to isolate trichomes from fresh or dry biomass.

This system is capable of processing up to 160kg of fresh frozen or up to 53 kg of dry biomass per run. Our WT-2000 is a large factory style system that requires large bay doors and high ceilings for installation and operation.

This system uses an innovative built-in CIP system which allows full cleaning of the system without any additional skid. The WT-2000 has optional automation upgrades for the automatic removal of spent biomass, and automatic valve actuation.

Daily Hash Output: Up to 33,600g

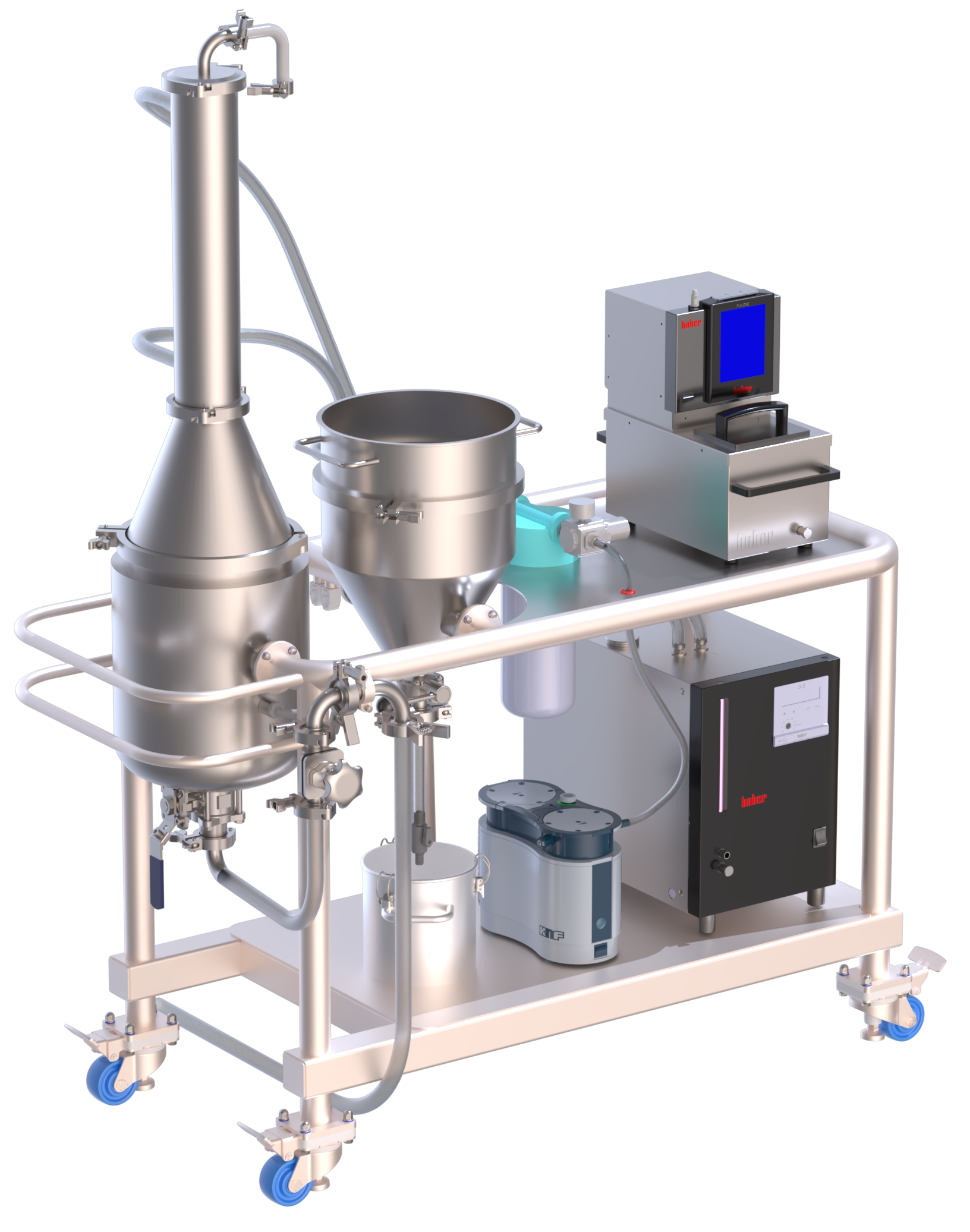

After isolation from plant matter, trichomes can be processed in a variety of methods. They can be air dried or lyophilized (freeze dried) for hash and then pressed into rosin.

Alternatively, we can process fresh bubble hash into edible oil using our TERP Reactor. Our innovative Terpene EnRichment Process (TERP) infuses fresh bubble hash directly into an edible carrier, creating a terpene-rich decarboxylated edible oil without the need for drying.

This process captures the terpenes which would have otherwise been lost in the conventional drying, extraction, and decarboxylation practices used today.

Using hash from fresh-frozen cannabis, this process can create edible extracts with higher terpene contents than dried cannabis of the same strain. We call the resultant oil Beyond Full Spectrum(™) because it is unlike anything seen in the market before it.

When coupled with our ice water extraction, the entire process of turning biomass into an edible oil uses only water, ice, and the carrier oil of your choice. This makes the process sustainable, cost effective, and organic, while producing the best possible product.

The TR-12 has a capacity of up to 3kg of wet resin, or up to 1.5kg of dry resin. This will produce up to 6 litres of finished oil.

After isolation from plant matter, the trichomes can be processed in a variety of methods. They can be air dried or lyophilized (freeze dried) for hash and then pressed into rosin.

Alternatively, we can process fresh bubble hash into edible oil using our TERP Reactor. Our innovative Terpene EnRichment Process (TERP) infuses fresh bubble hash directly into an edible carrier, creating a terpene-rich decarboxylated edible oil without the need for drying.

This process captures the terpenes which would have otherwise been lost in the conventional drying, extraction, and decarboxylation practices used today.

Using hash from fresh-frozen cannabis, this process can create edible extracts with higher terpene contents than dried cannabis of the same strain. We call the resultant oil Beyond Full Spectrum(™) because it is unlike anything seen in the market before it.

When coupled with our ice water extraction, the entire process of turning biomass into an edible oil uses only water, ice, and the carrier oil of your choice. This makes the process sustainable, cost effective, and organic, while producing the best possible product.

The TR-50 has a capacity of up to 12kg of fresh resin, or up to 6kg of dry resin. This will produce up to 25 litres of finished oil.

After isolation from plant matter, the trichomes can be processed in a variety of methods. They can be air dried or lyophilized (freeze dried) for hash and then pressed into rosin.

Alternatively, we can process fresh bubble hash into edible oil using our TERP Reactor. Our innovative Terpene EnRichment Process (TERP) infuses fresh bubble hash directly into an edible carrier, creating a terpene-rich decarboxylated edible oil without the need for drying.

This process captures the terpenes which would have otherwise been lost in the conventional drying, extraction, and decarboxylation practices used today.

Using hash from fresh-frozen cannabis, this process can create edible extracts with higher terpene contents than dried cannabis of the same strain. We call the resultant oil Beyond Full Spectrum(™), because it is unlike anything seen in the market before it.

When coupled with our ice water extraction, the entire process of turning biomass into an edible oil uses only water, ice, and the carrier oil of your choice. This makes the process sustainable, cost effective, and organic, while producing the best possible product.

The TR-200 is a larger scaled piece of equipment, aimed at helping our WT-2000. The TR-200 has a capacity of up to 48kg of wet resin, or up to 24kg of dry resin. Expect up to 100 litres of finished oil from this system per run.

Whistler Technologies equipment is designed to the highest quality and sanitary standards.

Quality is integral to us, so when we design equipment we ensure even the smallest components are engineered to perfection.

All of our equipment features:

2020 Whistler Technologies All Rights Reserved