There is a new movement making news in the hashmaking world: iceless cannabis extraction. Recently, the idea that ice may not be as essential as we once thought has come to light.

Over at Whistler Technologies, we have been hard at work conducting extensive research and development surrounding iceless extraction.

Ice was always thought to help in the agitation process, in addition to keeping things cold.

This may be true for those using outdated agitation technology, such as bottom mixers and large slow-moving paddles. However, we are finding that after a certain point ice can excessively impact the biomass. As a result, unwanted contaminants come off the material.

Modern equipment and lab installations bring forth new innovations, which facilitate iceless solventless cannabis extraction.

Equipment

Prior to getting into the details of iceless cannabis extraction, it is important to examine what equipment is required.

A water chiller is the first auxiliary to consider. Depending on specific requirements and budget, a chiller that can maintain the lab supply water between 0.5-5° C is necessary.

Next, it is important to use an agitator with a flow pattern that is optimized for iceless cannabis extraction.

Iceless processing allows for up to 50% more processing capacity. However, to extract the additional material efficiently without ice, the agitator must be engineered to create a controllable fast-moving flow pattern. It is important to have a flow pattern that imparts a high fluid flow over the trichomes, without an immense shear force that will shred biomass.

The Whistler Technologies patented torus flow pattern is fully tuneable, and provides the most efficient flow pattern for iceless agitation.

Using a mixing impeller, direct control of the flow of the mixture as a whole is achieved. The operator is able to easily tune the flow to achieve an efficient extraction. This can be done without extending process time, reducing final quality, or worrying about blowing a motor during production.

A back-and-forth motion only truly agitates in the instant where the direction changes. As a result, it will take longer to achieve an efficient extraction. The flow is also difficult to tune and will have to be over-powered to compensate for the additional material. This is likely to cause excessive machine wear, and contaminants in the hash.

When paired with a glycol jacket, the back-and-forth motion is also likely to freeze water to the walls of the tank. This is because the flow slows down before it changes direction. If the process water freezes to the walls of the tank, trichomes freeze with it. Every trichome matters!

Similarly, bottom mixing is also not ideal for iceless extraction. Bottom mixing agitates by moving only the water at the bottom of the tank. It then produces flow throughout the vessel, which creates agitation in the mixture of biomass and the water above.

As more biomass is added to increase extraction capacity, the mixture becomes harder to move using this method. This results in longer extraction times and excessive wear on the equipment.

Finally, it is important that the processing lab has environmental control. This allows for cooler ambient temperatures, ideally between 4 -10°C.

Process Time

Iceless cannabis extraction improves process times. As a result, it allows processors to spend more time processing additional biomass, packaging, or keeping the lab clean.

It is common to see a water supply temperature between 15-20°C. Some operators fill the agitation tank with warm water in advance, and then use a large amount of ice to cool it before adding their cannabis.

By utilizing both a glycol chilling system in the agitation tank and a water chiller, ideal water temperatures are achieved instantly. There is no longer a need for excessive manual handling, or ice machine maintenance.

This process is not only quicker, but it also reduces labour. An operator is no longer required to cool process water. This gives the operator more time to perform other tasks.

Yields and Quality

The removal of ice from the agitation tank leaves more space for cannabis. Through extensive research and development, we have found that as much as 50% more biomass can be added to Whistler Technologies agitation tanks, when operating without ice.

Additionally, the impeller can run at higher speeds. This creates higher forces across the trichome head and stalk connection, which have not been possible to date. Higher forces result in a more efficient process.

Some of our customers have been experimenting with iceless extraction, using their Whistler Technologies systems. The feedback we are receiving is that yields are increasing, as processing times are decreasing. All while quality remains the same, or in many instances. improves.

Producers that were previously achieving a 4% average yield (from FF to dry hash) have seen their yields increase to as much as 5.5-6%, from the same starting material.

This significant yield increase comes with a heavily reduced agitation time. What once took upwards of two hours to obtain a 4% yield, now takes around an hour and yields 5.5-6%, of the same or better quality hash.

This remarkable improvement to your bottom line is made possible due to the extensive R&D done here at Whistler Technologies. Our engineering team works hard to create the most efficient, highly controllable and ‘true’ agitation pattern.

The Best System for Iceless Cannabis Extraction

There is no better system to set up iceless cannabis extraction, than the WT-CRAFT+.

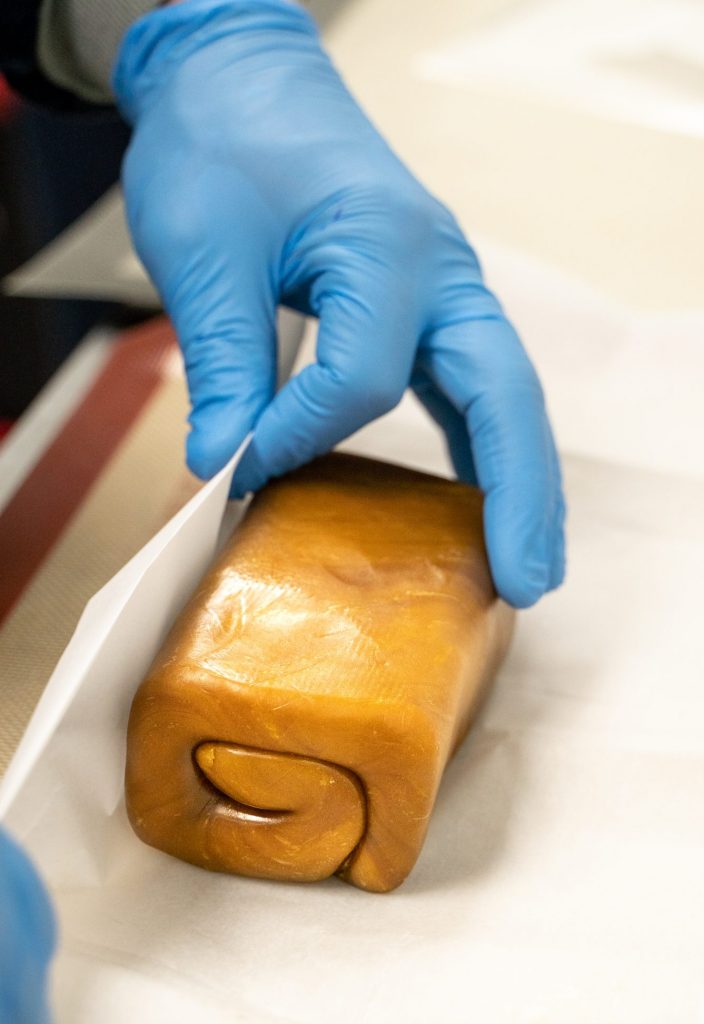

The WT-CRAFT+ was designed with iceless extraction in mind. The continuous flow filtration, hash specific separator, 220-micron false bottom, and torus flow agitation truly allow operators to optimize iceless processing. Pulling bags becomes nearly impossible while working with the amount of hash that comes off a 40kg fresh frozen run!

For those with existing ice machines, fear not. Ice can be added to the catchment reservoir of the WT-CRAFT+. This way, you can take advantage of the benefits of iceless agitation, while still achieving continuous cooling of the process.

Speak to us today to learn how iceless operation can streamline your extraction process, while improving the profitability and sustainability of your business.