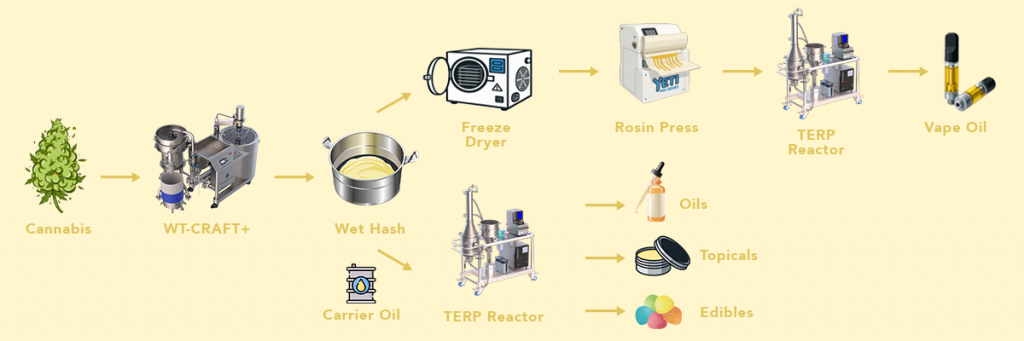

MAKING CANNABIS OIL, VAPES, OR EDIBLES?

Unlock the full potential of your cannabis extracts with our Terpene Enrichment Process (TERP) Reactor.

Produce cannabis extracts that go beyond traditional full-spectrum products, by preserving a comprehensive range of cannabinoids, terpenes, and other beneficial plant compounds from living trichomes. Our TERP Reactors allow you to decarboxylate your “live” cannabis extracts without losing terpenes.

Our patented TERP process preserves the cannabis strain’s natural terpene profile.

Terpenes aren’t just about taste—they enhance therapeutic effects.

The least adulterated form of cannabis oil, retaining the plant’s natural essence without unnecessary additives, solvents or post-processing.

Cannabinoids, terpenes, and plant compounds work together for a stronger, more effective experience.

Traditional decarboxylation methods apply heat under a vacuum or in containers, which causes terpenes and volatile compounds to escape. As they evaporate, so does your product quality.

Some producers try to fix this by adding terpenes back in or using extra refinement steps. This adds cost, time, and often results in a product that feels artificial.

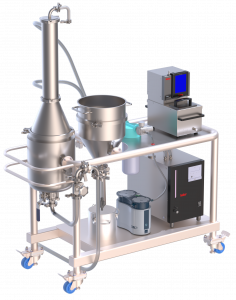

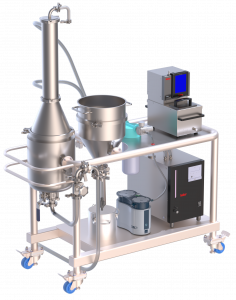

The TERP Reactor features a condensing column which captures any escaping volatiles, returning them to your cannabis extract as CO2 escapes.

The result is spectacular—an extract rich in native terpenes, flavour, and therapeutic potential. Alternatively, you can capture terpenes and separate them from your extract while it decarboxylates.

Save the terps!

Whistler Technologies’ TERP reactors turn wet hash directly into an edible oil—no need to dry your hash. The result? Maximum terpene retention, quicker turnaround, and significantly lower operational costs.

The term ‘full-spectrum’ is everywhere—but ‘full-spectrum’ doesn’t have a specific definition, and many products marketed as such are missing something big: terpenes.

These delicate compounds give cannabis its aroma, flavour, and contribute to the entourage effect. Yet, because terpenes are volatile they’re often lost during extraction and decarboxylation. Traditional methods simply can’t preserve them in edible oils.

The TERP Reactor changes that. By maintaining low temperatures and vacuum conditions, it captures not just THC and CBD, but also minor cannabinoids, flavonoids, and the full terpene profile—creating Beyond Full Spectrum™ oils that are richer, more effective, and more true to the plant.

For edible formats like gummies and sublinguals, and smokable formats like vape carts, this means a deeper, more complete experience—without added steps or synthetic flavouring.

Just pure, potent plant power.

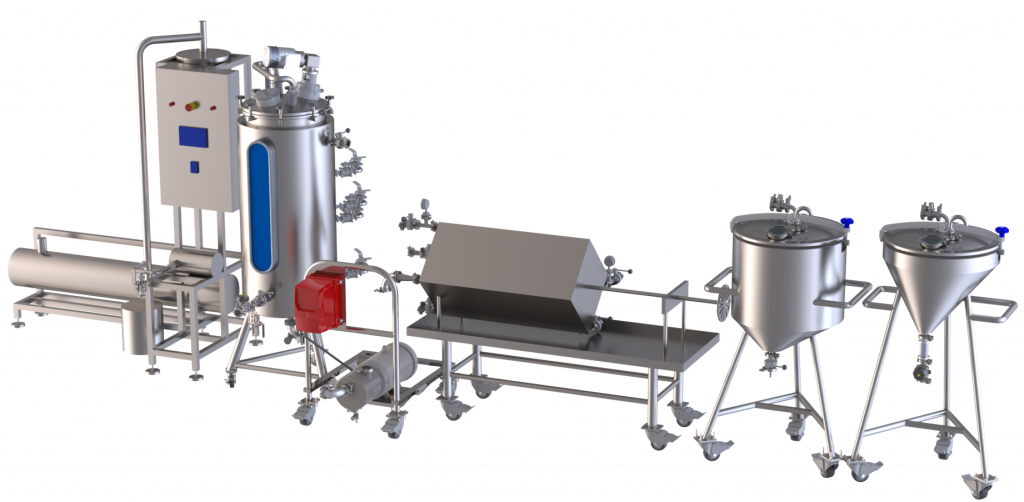

No matter your operation’s scale, there’s a TERP Reactor for your lab.

Each model delivers the same powerful benefits—no drying, no solvents, and Beyond Full-Spectrum™ oil production with maximum terpene retention. Just choose the size that fits your workflow and start infusing smarter.

Our line of TERP Reactors is designed according to GMP standards. Every TERP Reactor we build maintains the highest standards of quality, compliance, safety, and cleanliness.

At Whistler Technologies, we employ a 20-point customer plan to ensure we deliver equipment which will adhere to the most stringent GMP standards. This process guarantees that our team understands the scope of customer projects and enables us to identify and resolve any issues during the project delivery.

Ready to go Beyond Full-Spectrum™?

2020 Whistler Technologies All Rights Reserved